Understanding semiconductor facts is crucial for companies to sustain the age of 5G, AI, cloud computing, electric vehicles, and IoT. This industry is the foundation of modern electronics. Whether smartphones or laptops, electric cars roving the roads, or planes flying overhead, semiconductors facilitate the working of these amazing wonders. These are the integral aspect of electronic devices, allowing advancements in numerous fields like medicine, defense, energy, transmissions, computing, and many others.

As technology evolves rapidly, such companies have a vast scope for opportunities to profit. This article will outline 10 facts about the semiconductor industry. Covid 19 has affected almost all sectors, but this field has managed to recover quickly and progress further.

China is the largest investor in the semiconductor industry

Many countries are investing in this domain due to its infinite scope and profitability. China is at the top as far as investments are concerned. In the year 2020, China invested a whopping amount of 35.2 billion dollars. It is interesting to note that it is also the largest manufacturer and consumer of semiconductors. It has registered almost 15 k firms in 2020.

The Big Fund, established by China, is designed to sponsor chip manufacturing and design and facilitate mergers as well as acquisitions. This country is planning to become self-sufficient in this stream by 2025.

By 2025, smartphones will be the leading application

The semiconductor industry is developing image sensors for smartphones which are highly in demand. This will become the dominant application within the industry by 2025. According to projections, the smartphone market will reach 162 billion USD by 2025, from 116 billion USD in 2020.

This revolution began in March 2020 with Huawei’s P40 series. That was the first series to use 50MP image sensors in smartphone design. These sensors were quickly adopted by other OEMs, like OPPO and Vivo. Recent unveilings by Samsung Electronics Co. include the 200MP ISOCELL HP3 image sensor. The 0.56 micrometer (μm)-pixels sensor will let fabricators provide enhanced resolution with reduced module area.

Global semiconductor sales have reached 50.92 billion dollars

Global semiconductor sales rose to 50.92 billion US dollars in April 2022, up from 50.58 billion US dollars in March 2022. Talking about the regional markets, China leads the way by becoming a substantial individual market followed by Asia and America. The global semiconductor market reached its peak thanks to growth in key regional markets and product categories.

Samsung is the biggest semiconductor company on this planet

In 2021, Samsung became the top semiconductor company with a market share of 12.3%. This South Korean company has beaten the United States chipmaker Intel which was on the top of the list for many years.

The U.S. semiconductor industry accounts for around 50% of the global market, ahead of several Asian countries like Japan, South Korea, China, and Taiwan. Along with Intel, Micron Technology, Qualcomm, and Broadcom are notable U.S. semiconductor vendors.

Various applications, including smartphones, computers, and data centers, are catalysts that are driving the demand. As cars become intelligent and more connected, semiconductors for the auto industry are also estimated to expand on a large scale. In 2021, however, a shortage of semiconductors caused a slowdown in vehicle production for several major automakers and suppliers.

Intel is the semiconductor giant in the US

In 2021, Intel generated $73.1 billion. Headquartered in Santa Clara, California, this is considered a giant in semiconductor chip manufacturing. This company is expanding to be a major supplier of foundry capacity in Europe and the United States. Intel has been at the top of the global market with a share of 10-15%. Its main competitors are Texas Instruments, Samsung Electronics, Micron Technology, Broadcom, and Qualcomm.

Intel’s processors, products, and technologies are high in demand and expected to achieve much higher revenue by the end of 2022.

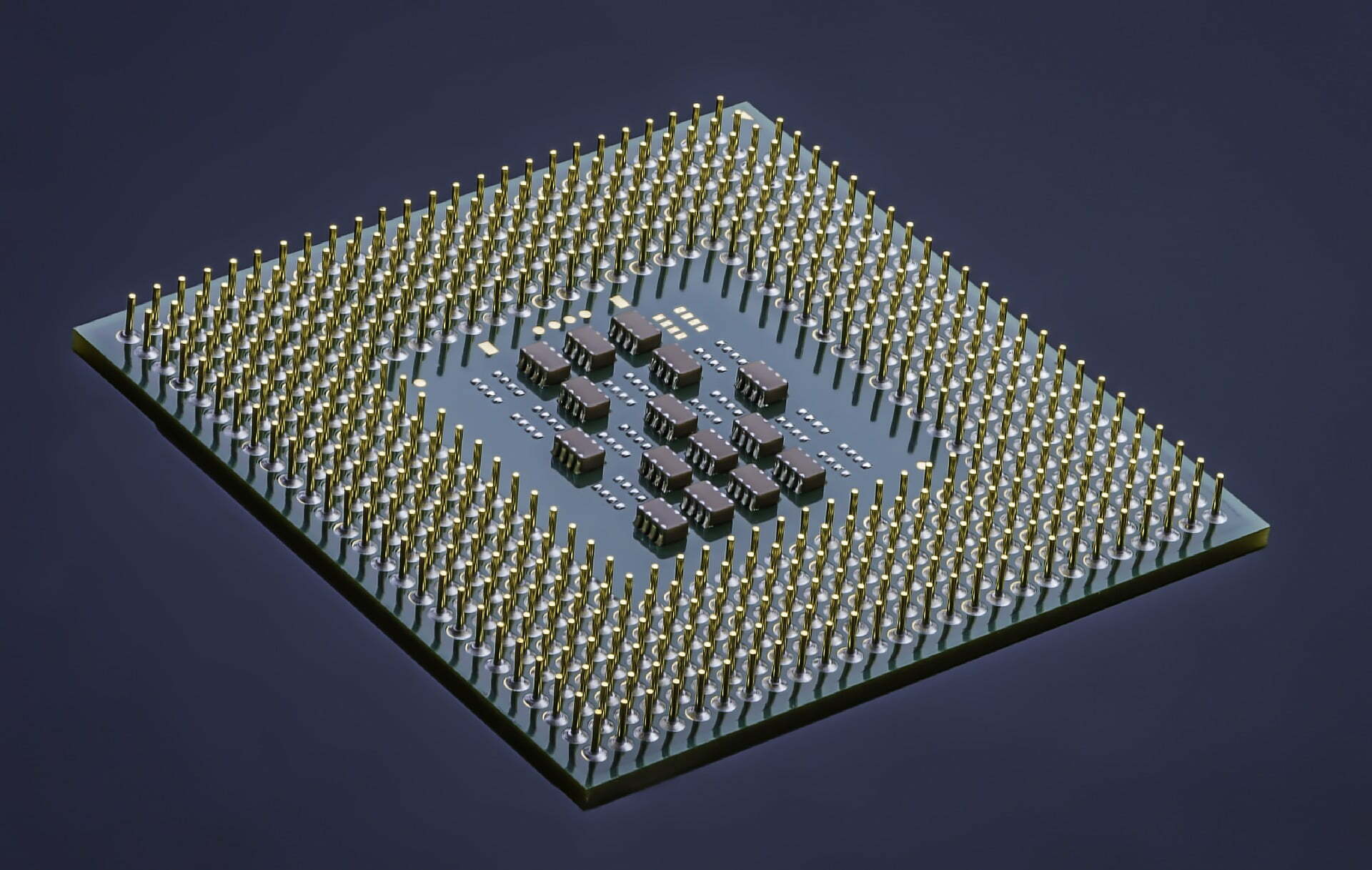

MOSFET is the most used semiconductor device

Metal–oxide–semiconductor field-effect transistor, popularly known as MOSFET, is a device manufactured with Silicon material. It is the primary component of most modern electronics, such as memory, image sensors, processors, and ICs. Each microprocessor and memory device contains thousands to billions of integrated MOSFETs to perform basic switching functions.

Gadgets, clocks, calculators, electronic voting machines, home and kitchen applications, lighting, LEDs, gaming, etc., are among the typical applications of MOSFET. Moreover, this device dominates different sectors such as automotive, space, telecommunications, avionics, and IT.

Silicon is the widely used material in the fabrication of semiconductor device

It is interesting to note that silicon is the second most abundant and easy-to-obtain material on the earth after oxygen. In addition to soil and rocks, silicon is also found in natural water, plants, and trees. Silicon, however, originates as a mixture of Oxygen, Aluminum, and Magnesium. This requires the extraction of silicon from the compound followed by purification. There is a great deal of power consumed in the process of purifying it. One of the key semiconductor facts is that a single crystal structure must be 99.999999999% pure.

This material is stable and a perfect fit for semiconductors.

India is investing 30 billion dollars in the semiconductor supply chain

By considering the demand surge in semiconductors, India is planning to invest 30 billion dollars in the supply chain of this stream. As per reports, a total of $10 billion will be spent on two chip facilities and display factories. Almost $7 billion will be allocated to the electronics industry, which includes giants like Foxconn and Pegatron, the iPhone assembler. It is anticipated that the remaining $13 billion will be utilized for affiliated services such as networking, telecommunications, refined chemistry, solar photovoltaic, and battery cells. This endeavor will facilitate the production of displays, networking, and electronic supplies. The estimated requirement will hit $110 billion by 203.

Approximately 3 months are required to make 1 chip

It usually takes more than three months to manufacture a chip, which requires giant factories, dust-free rooms, multimillion-dollar machinery, molten tin, and lasers. Ultimately, silicon wafers transform into a network of billions of transistors, which form the basis of the circuitry of devices such as phones, computers, cars, washing machines, and satellites.

This process involves complex steps such as Oxidation, Lithography, Baking, Etching, Doping, Metal deposition, and Wafer formation. According to ISO 14644-1, cleanrooms belonging to class 100 are recommended for such production. A cleanroom is an enclosed space that reduces particulate contamination and controls other environmental factors such as humidity, temperature, and pressure.

Read more, a journey into the world of PCB manufacturing.

Asia Pacific is the world’s huge market

In the Asia Pacific, the Chinese Mainland, Japan, South Korea, and Taiwan are among the top four markets by revenue thanks to their government support, a large market, and increased R&D spending. Globally, Asia Pacific accounts for 60% of semiconductor sales. South Korea is the world’s second-largest semiconductor nation after the United States, while Taiwan has the biggest foundry in the world. One of Japan’s strengths is its ability to produce high-purity semiconductor materials upstream.

With semiconductors, we can open doors for endless possibilities and accelerate technological development. For the latest trends like IoT and AI, companies are hoping to yield insight from huge data volumes. First and foremost, there will be a computing challenge. A new era of computing will be marked by high-performance hardware systems and a new fraternity of chips. In turn, this will force established companies to improve their computing platforms and solutions in terms of power consumption. Secondly, one of the biggest questions for semiconductor companies is reducing the time to market. Addressing these issues will help mitigate future challenges.

These semiconductor facts will decide the future of the digital revolution.

[…] we know, semiconductor manufacturing involves multiple steps, so as PCB manufacturing. The step-by-step approach is […]

[…] Various industries require ISO certification, including manufacturing, food, energy, medical, semiconductor, etc. Even though ISO sounds simple, it has a vast vocabulary that consists of different […]

[…] from commercial giants around the globe. Different industries like automotive, electrical, semiconductor, etc., are also planning to use it for their trademark protection. Recently, Mercedes Benz applied […]