Industrial exoskeletons are protective coverings designed to ease the mechanically straining activities of human labor. Several industries require human precision in certain operations, even in this age of AI or automation. According to a recent survey, the global industrial exoskeletons market will likely expand to USD 2.03 billion by 2030. These wearable tools will support the human physique by increasing strength and reducing strain. These devices are now revolutionizing workplaces across various industries, including manufacturing, construction, and logistics.

- What is an Industrial Exoskeleton?

- Types of Industrial Exoskeletons

- How Companies Can Adopt Industrial Exoskeleton Technology

What is an Industrial Exoskeleton?

Industry 4.0 demands technological evolution. It is progressing toward the integration of humans and robots for a unified system. It protects human health while optimizing productivity. An exoskeleton is a tool that enables the processing of mechanical power and information signals. This wearable device can lessen human fatigue, support operations, and increase the productivity and quality of both the human worker and the intended activity.

Industrial exoskeletons can assist with:

- Supporting posture during operations that demand extended bending and overhead work

- Supporting lifting to carry out the heavy load

Exoskeletons enhance endurance and reduce the risk of injury.

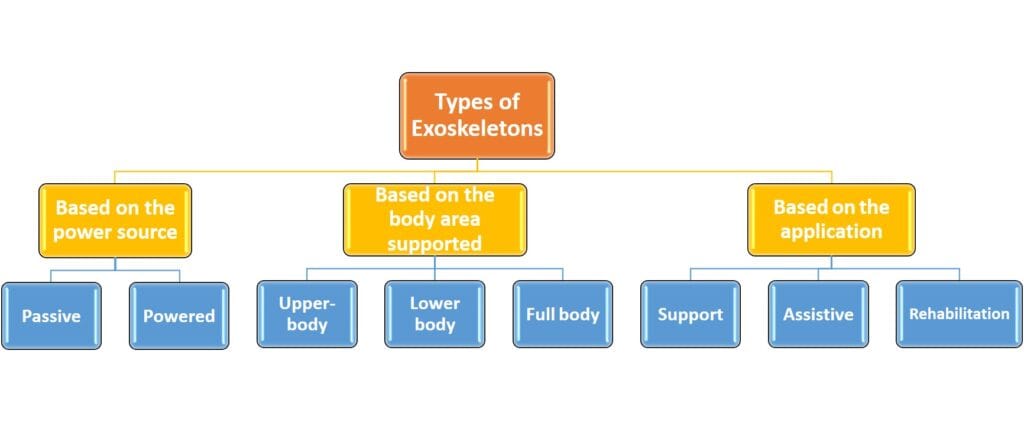

Types of Industrial Exoskeletons

Industrial exoskeletons come in different forms, each designed for specific industries, workloads, and body support needs. They can be categorized according to application, power source, and the body supported areas.

Based on Power Source

Passive Exoskeletons

These devices can function using springs, counterweights, or elastic bands to offload strain from muscles and joints. They don’t require motors or batteries to operate. They can be used in automotive assembly, packaging, warehouse sorting, and light construction.

- Advantages:

- Lightweight and portable

- Lower cost ($1,000–$5,000)

- Easy maintenance

- Limitations:

- Provide posture support but do not amplify strength.

- Examples:

- Levitate AIRFRAME was used by the Boeing aircraft assembly team to lessen arm fatigue during overhead wiring and drilling tasks, which reduced shoulder strain by up to 80%.

- SuitX BackX was adopted by Lowe’s warehouse staff to reduce lower-back injuries during lifting, which contributed to a 25% drop in back strain complaints.

Powered Exoskeletons

These are equipped with electric motors, hydraulics, or pneumatics to assist movements in shipbuilding, heavy manufacturing, defense logistics, and aerospace sectors. These devices are controlled by motion sensors or AI algorithms.

- Advantages:

- Significantly amplifies lifting power (up to 90 kg in some suits)

- Ideal for continuous heavy-load handling

- Limitations:

- More expensive ($25,000–$80,000+)

- Heavier and require operator training

- Examples:

- Sarcos Guardian XO was used in shipbuilding yards to lift and transport 45 kg (100 lbs) steel components repeatedly without strain, cutting assembly time by 20%.

- Hyundai H-VEX is tested in car manufacturing plants for tasks involving forward-bending positions. Workers reported a 40% reduction in lower-back muscle activity.

Based on Body Area Supported

Upper-Body Exoskeletons

These tools support arms, shoulders, and neck for tasks that involve overhead or forward-reaching positions. EksoVest (Ekso Bionics) was deployed in Ford assembly plants for overhead installation work. Workers experienced a 70% reduction in neck and shoulder strain.

Lower-Body Exoskeletons

These industrial exoskeletons provide support to the hips, thighs, knees, and lower back during lifting, squatting, or standing for long periods. SuitX LegX was used in logistics warehouses where staff spend hours crouching to stack packages. Reduced knee discomfort led to a 15% improvement in task completion speed.

Full-Body Exoskeletons

They support the entire body for tasks involving both heavy lifting and posture correction. For example, Guardian XO was tested in construction to move large steel beams without cranes in certain scenarios, allowing faster site setup and reducing reliance on manpower.

Based on Application

Support Exoskeletons

These designs are usually passive, which redistributes the load to reduce fatigue and injury risk. Levitate AIRFRAME in automotive paint shops reduced repetitive motion strain, resulting in fewer worker absences due to muscle injuries.

Assistive Exoskeletons

Assistive exoskeletons are powered designs that add strength for lifting or holding heavy loads. In oil and gas maintenance, Sarcos Guardian XO supported workers to hold a heavy drilling machine without putting any tension on their muscles.

Rehabilitation & Return-to-Work Exoskeletons

These devices support wounded workers in regaining strength and rejoining the workforce. ReWalk Industrial Adaptation in manufacturing plants transitioned recovering employees back to light-duty roles.

Benefits of Using Industrial Exoskeletons

- Reduced Risk of Injury

- Less tension on muscles and joints, particularly in the back, shoulders, and knees.

- Fewer occurrences of workplace musculoskeletal disorders (WMSDs).

- Improved Productivity

- Workers can do tedious and physically straining tasks for longer without getting tired.

- Helps maintain consistency in quality and performance.

- Better Worker Retention

- Lower injury rates and reduced exhaustion lead to higher job satisfaction.

- Cost Savings for Companies

- Fewer injury-related claims.

- Reduced downtime due to accidents.

Leading Industrial Exoskeletons in the Market

The exoskeleton industry is evolving, shifting from experimental prototypes to industry-ready tools. Several companies are designing ergonomic, efficient, and task-specific exoskeletons for manufacturing, logistics, construction, and even healthcare.

Ekso Bionics (USA)

This company has two Flagship Models, including EksoVest and EksoNR. EksoVest is a passive, upper-body exoskeleton designed for overhead tasks in assembly lines of the automotive and aerospace sectors. EksoNR is a robotic tool for stroke and spinal cord injury patients.

Sarcos Robotics (USA)

Guardian XO is a full-body powered exoskeleton capable of lifting up to 90 kg (200 lbs). It is ideal for heavy-duty tasks in construction, logistics, and defense. It is battery-powered, with intuitive motion control and high payload capacity.

Ottobock (Germany)

This company has manufactured Paexo Shoulder and Paexo Back

Paexo Shoulder supports arms during overhead work, reducing shoulder and neck tension. Paexo Back aids in lifting tasks, supporting the lower back. These models are light, have a breathable design, and an adjustable fit, without requiring any power.

Comau (Italy)

This company has designed MATE (Muscular Aiding Tech Exoskeleton), a passive upper-body exoskeleton for manufacturing and logistics. It is programmed to mimic natural human movement while minimizing muscular tension.

It was adopted in various Fiat Chrysler Automobiles (FCA) plants to support repetitive assembly tasks. It has an ergonomic design, adjustable resistance levels, and easy wearability.

Robo-Mate (EU Consortium)

It is a modular exoskeleton system for industrial and logistics tasks. It is designed for flexibility. It was tested in various European automotive plants, showing up to 40% less worker fatigue.

Levitate Technologies (USA)

This industry has developed Airframe, a passive, upper-body exoskeleton for industrial assembly work. It transfers arm weight to the body’s core to lessen shoulder strain. It is very light, offers minimal restriction on movement, and is easy to integrate into work uniforms.

It was used in Boeing facilities for prolonged overhead riveting and drilling tasks.

How Companies Can Employ Industrial Exoskeletons

The successful adoption of industrial exoskeletons requires a structured and strategic approach that aligns with an organization’s operational needs, workforce dynamics, and long-term productivity goals.

Conduct a Comprehensive Needs Assessment

Before investing in this trend, organizations must evaluate where it can deliver the highest return. This involves:

- Ergonomic Risk Analysis: Identifying high-strain tasks such as repetitive lifting, tedious work, or extended bending.

- Job Role Prioritization: Targeting departments or roles with the highest injury rates or ergonomic risks.

- Operational Compatibility: Ensuring exoskeletons do not delay movement in congested workspaces.

Ford Motor Company deployed industrial exoskeletons only after a detailed study revealed that certain assembly-line stations involved repetitive overhead work, resulting in high rates of shoulder injuries.

Choose the Right Type

Different industries require different types of exoskeletons:

- Passive Exoskeletons for reducing fatigue in repetitive tasks without using batteries.

- Powered Exoskeletons for heavy load handling and tasks requiring mechanical assistance.

- Specialized Models for tasks like welding, construction, or logistics.

In construction, Hilti uses passive exoskeletons for overhead drilling tasks, while logistics companies like DHL use powered exosuits to assist with heavy package handling.

Pilot Testing and Feedback Loop

Instead of a large-scale rollout, organizations should start with a pilot program:

- Choose a small group of people to test the tools for a specific duration.

- Gather feedback on comfort, strength, and effectiveness.

- Record metrics on productivity improvement, injury reduction, and downtime.

Boeing introduced exoskeletons to select maintenance crews and used pilot data to refine their integration strategy before the expansion.

Integrate with Safety and Training Programs

Even the most advanced industrial exoskeletons require proper training for optimal use.

- Operator Training: Workers must learn correct wearing, adjustment, and movement techniques.

- Maintenance Training: Supervisors or in-house technicians should be trained in device maintenance to ensure uptime.

- Safety Compliance: Ensure the exoskeleton design and use comply with OSHA or equivalent workplace safety regulations.

Establish KPIs and ROI Metrics

To justify the investment, companies should set measurable performance indicators:

- Reduction in workplace injuries and related compensation claims.

- Improvements in task completion time and efficiency.

- Decrease in worker fatigue and absenteeism.

Create a Culture of Acceptance

Technology adoption is often restricted by employees who fear discomfort or job changes.

- Involve workers early: Seek their input during the decision-making stage.

- Highlight benefits: Communicate how industrial exoskeletons will protect their health and extend career longevity.

- Provide incentives: Recognize early adopters and ambassadors of the technology.

Scale and Evolve

Once initial deployments show positive results, companies can expand adoption:

- Introduce more advanced models as technology evolves.

- Customize devices for specific job roles.

- Collaborate with exoskeleton manufacturers for tailored solutions.

Toyota started with basic passive suits in its Japanese plants and then shifted to powered industrial exoskeletons for high-load assembly work after witnessing a measurable productivity boost.