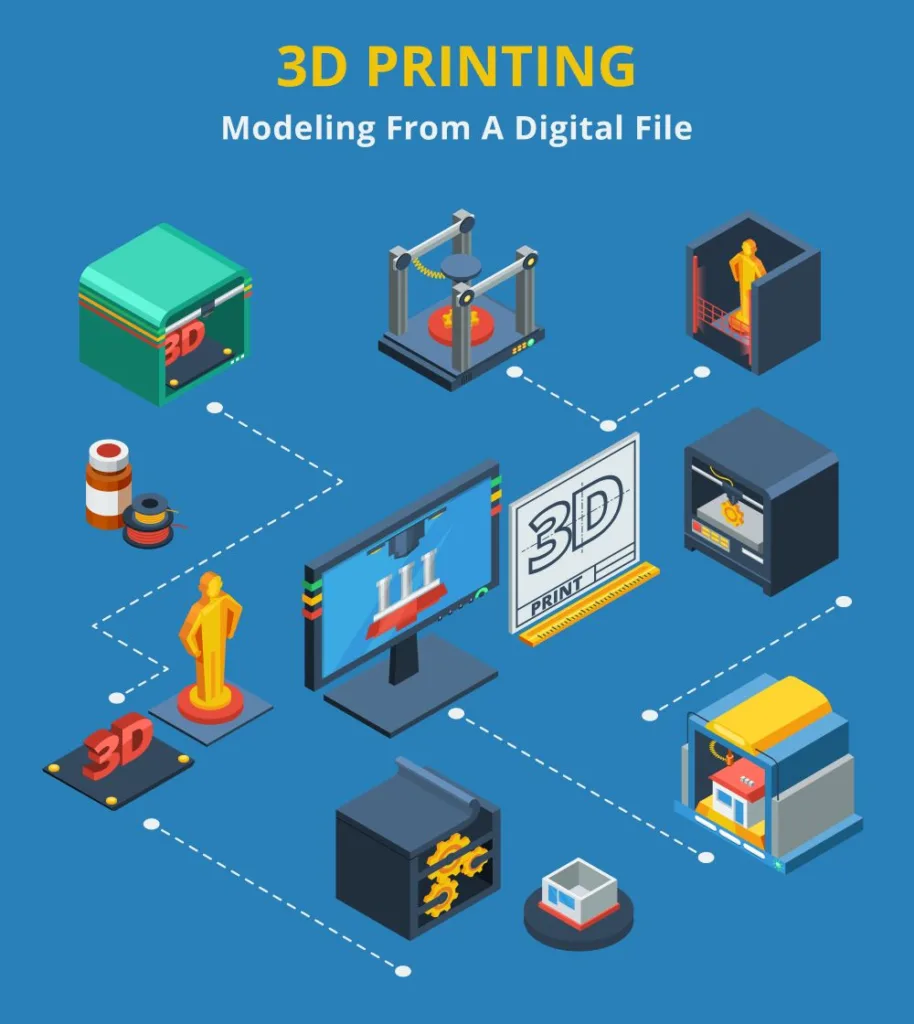

3D printing is simply the art of creating physical outputs from digital inputs. This phenomenon has taken the world by storm as it eliminates traditional subtractive processes with additive ones. Due to its numerous advantages, it is reaching homes, industries, medical, automobile, and many other fields.

3D printing covers all sorts of needs whether it’s prototyping, replacement parts, or a well-designed CAD model. A good state-of-the-art example could be the construction using bricks. Bricks are added layer-by-layer using a drawing made by engineers or architects. This is how the whole layout is built. 3D printing is exactly like that!

What is 3D printing

As previously stated, 3D printing is the process of adding material layers to create physical objects as per the digital design. It is a form of additive manufacturing that is the opposite of subtractive manufacturing. For the subtractive method, consider wood carving or machining using a CNC machine, where the material is cut or milled to form the desired pattern. In this technique, 3D printers receive input virtually and the installed robotic devices lay up structures accordingly. There are three classes to accomplish this: selective binding, selective solidification, and selective deposition.

Selective binding: Here, a powdered mixture of gypsum and metal is combined with heat or binding catalysts to merge the particles and thereby forming the object. Laser blends the molecules and forms a base or a platform. Then, simultaneously other layers are added over one another.

Selective solidification: Through this procedure, liquids are solidified one layer at a time by applying energy that results in a product. First, the liquid is poured onto the base, which is then submerged in another layer. Later, this needs to be cured to make a finished product.

This is similar to photolithography or laser direct imaging used in PCB manufacturing. Lasers along with the UV light harden the resin and print the image on a substrate layer.

Selective deposition: It precisely deposits the material in required places. Filament-based printers work exactly this way.

Difference between additive and subtractive manufacturing

| Additive manufacturing | Subtractive manufacturing |

| Layer-by-layer addition of material | Layer-by-layer removal of material |

| Suitable for creating intricate shapes or patterns | Little capacity to manufacture delicate parts |

| Little to no material wastage | A significant amount of material waste is in the form of chips, burrs, etc. |

| Relevant for a limited range of materials | Suitable for a wide variety of materials |

| Appropriate for dedicated products | Feasible for mass production |

| Expensive | Economical |

| Works without human intervention | Require human involvement |

If you want to learn about new age trends such as predictive maintenance, cobots, extended reality, etc., read our article on the top 7 manufacturing trends to watch out for.

A step-by-step guide to 3D printing

Creating a 3D model

A 3D model is a prerequisite for this printing. It can either be created on our own, designed with CAD software, or scanned using an existing model. STL (Surface Tesselation Language) is the most common file format that exists in binary and ASCII versions. This is a simple format consisting of triangles covering the shape of the object. Other formats like OBJ and AMF are also extensively researched. Refer to the below important points:

- Models should not have any holes or cavities on their surfaces.

- Many images of a single object can be scanned from different angles and collectively used to make a 3D representation. Appropriate scanning depends on the selection of the scanner, reflections, and quality of images.

- For medical and scientific purposes, CT scanners can be used to capture details information about specific parts. Such high-resolution images play an important role in 3D printing.

- Models of everyday things are generally present in the image database. It is possible to directly download and modify the existing models as per the need.

- For a new model preparation, CAD software is used that offers various features and commands suitable for our necessities.

Slicing a model

In this step, the model is divided into layers for printing. These layers are prepared considering the physical characteristics of the material, product geometry, as well as printer feasibility. This is like cooking a dish with proper ingredients. Here, ingredients can be different settings related to the printer that will achieve the intended result.

The main purpose of slicing is to break the complex geometry into simpler structures that will be understood by the printer. Sliced layers are comprised of one file named G-code. As the CNC machine performs all the operations using G codes and M-codes, the 3D printer also works the same.

Printing

In general, G-code can be loaded onto the printer from a computer via a USB port; however, some printers can read from SD cards as well. G-code commands are processed one at a time by a printer’s software and sent to the printer to execute. A USB cable sends status information back to the user’s computer. Some printers receive control signals from a host computer that runs a G-code interpreter.

After printing, the part gets created on the platform.

Applications of 3D printing

Medical

- Customized equipment and products

- Jigs and fixtures

- Surgical tools and implants

- Bioprinting tissues and organs

- Anatomical structures

- Dental implants

Industrial

- Toolings, parts, and prototypes for the aerospace industry

- Custom seats, replacement parts, tools, and end-use components for the automotive sector

- Drones for military

Consumer goods

- Footwear

- Beauty products

- Jewelry and art

- Bikes

- Construction

3D printing will bring out:

- Transformation in processes: It allows factories and supply chains to be more adaptable and agile. A number of features are included, such as digitization, decentralization, and the capability to create on-demand tools and spare parts.

- Revolution in products: It indicates the potential of developing new components and products, such as intricate lattice designs, complex geometries, and lightweight as well as customized components. It can also reduce the number of parts.

[…] development of 3-D printing in the consumer market will lead to the sale of cheap consumer-produced car parts and perhaps, in […]

[…] time based on 3D CAD models. Additive manufacturing describes a set of techniques that enable the 3D printing of physical […]