Smart factories represent a paradigm shift in conceptualized, designed, and executed industrial processes. This article explores details of smart factories, the intricate web of technologies, their applications, and the standardization of challenges.

What is Smart Factory

It is an advanced manufacturing facility that uses digital technologies, connectivity, and automation to create an efficient, responsive, and adaptive production environment. It formed from Industry 4.0 principles, combining physical and digital trends, setting a highly interconnected and intelligent manufacturing ecosystem.

Components of Smart Factories

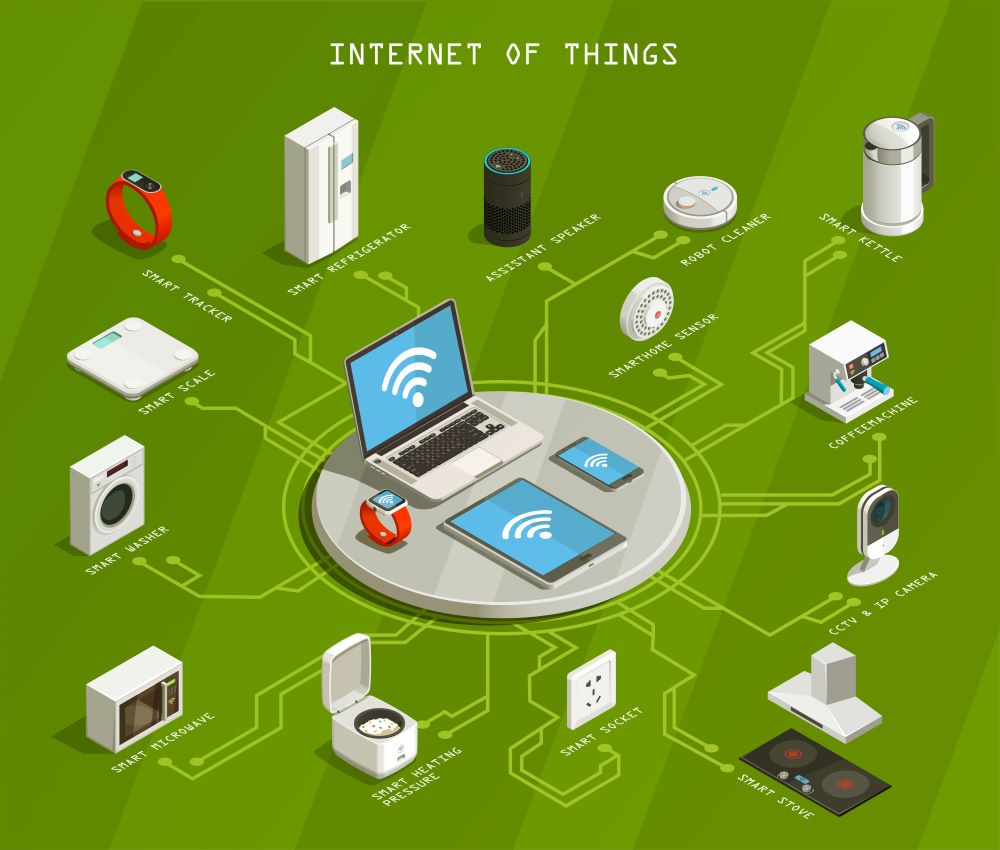

Internet of Things (IoT)

Smart factories involve the expansion of connected devices. The Internet of Things enables real-time data acquisition and exchange within the manufacturing ecosystem.

If you want to learn important concepts of IoT, refer to our article on know these 11 IoT FAQs to be smarter.

Artificial Intelligence (AI)

AI, including machine learning algorithms, plays a pivotal role in smart factories. These intelligent systems analyze vast amounts of data to derive insights, predict outcomes, and make informed decisions, enhancing operational efficiency.

Big Data Analytics

The massive influx of data generated by sensors and devices is harnessed through advanced analytics. Big data analytics filters through this information, uncovering patterns, trends, and correlations that contribute to strategic decision-making.

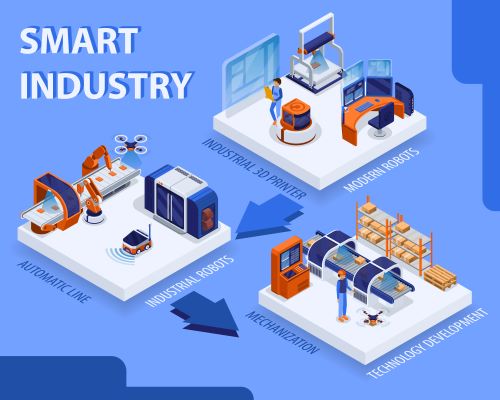

Automation and Robotics

Automation is a hallmark of smart factories. Robotics, including collaborative robots (cobots), work alongside human operators to perform tasks precisely and quickly. Automated processes reduce manual intervention, ensuring efficiency and consistency.

How does Smart Factory work

Connectivity and IoT Integration

The integration of IoT enables a broad view of the manufacturing process. IoT interconnects devices, machines, and systems. Sensors collect real-time data on parameters such as temperature, pressure, and production rates. This data is transmitted over networks that create a continuous flow of information.

Read more, how to build Robots using two fundamental elements.

For example, sensors on production equipment can communicate with inventory management systems, allowing for real-time adjustments based on inventory levels and demand forecasts. This interconnectedness enhances visibility and control over the production ecosystem.

Data Analytics and Artificial Intelligence

Advanced analytics processes the data collected from sensors. It then uncovers insights that are impossible to learn through conventional methods.

Machine learning algorithms are trained on historical data to understand patterns and correlations. These algorithms can then predict outcomes, such as potential equipment failures or fluctuations in demand. For example, if sensors detect an anomaly in the vibration patterns of a machine, the AI system can predict an impending failure and trigger a maintenance alert. This process is summarized in our predictive maintenance article.

Automation and Robotics

Robotics, ranging from robotic arms to autonomous guided vehicles (AGVs), are employed to handle repetitive, labor-intensive tasks or pose safety risks to human operators. Collaborative robots, or cobots, work alongside human workers, enhancing overall efficiency and safety.

In a smart factory, automation extends beyond the assembly line. Automated guided vehicles navigate the factory floor, transporting materials between workstations. Robotic systems handle tasks such as material handling, welding, and packaging. The result is a streamlined production process with minimal manual intervention.

Applications of Smart Factories

Improved Efficiency and Productivity

Real-time data monitoring and analysis enable quick decision-making, reducing downtime and enhancing overall operational output. For example, if a smart factory detects a bottleneck in the production process, it can automatically adjust workflows or allocate additional resources to optimize efficiency.

Flexible and Agile Production

Smart factories are to changes in demand and production requirements. The agility offered by advanced technologies allows manufacturers to reconfigure production lines, switch between products, and respond to market fluctuations.

Read our article on how to develop agile business.

Adapting to changes in product specifications or production volumes could be a time-consuming and resource-intensive process in a conventional setup. Smart factories, however, excel in flexibility. They can adjust production schedules, modify workflows, and accommodate last-minute changes with minimal disruptions.

This flexibility is advantageous in industries where customization and quick response to market trends are essential. For example, a smart factory producing consumer electronics can swiftly adapt to changes in product design or features based on customer feedback or emerging market trends.

Predictive Maintenance

Smart factories can anticipate equipment failures before they occur by analyzing data and applying predictive algorithms. This proactive approach lowers maintenance costs, reduces downtime, and increases the lifespan of critical assets.

Consider a scenario where sensors on a production machine monitor various parameters such as temperature, vibration, and lubrication levels. Through continuous analysis, the AI system can detect patterns indicative of potential issues, such as a worn-out bearing. The system then generates a predictive maintenance alert, prompting maintenance personnel to replace the bearing before it fails.

Enhanced Quality Control

Smart factories employ advanced sensors and cameras to monitor the production process in real-time. This constant surveillance enables immediate detection of defects or deviations from quality standards. Automated quality control mechanisms ensure that only products meeting stringent criteria reach the market, fostering customer satisfaction and brand reputation.

Read more about, 15 most valuable terms to understand ISO 9001:2015.

Limitations of Smart Factories

While the promises of smart factories are substantial, their adoption and implementation come with certain challenges and limitations.

Initial Implementation Costs

The transition to a smart factory requires a significant upfront investment in technology, infrastructure, and employee training. Small and medium-sized enterprises (SMEs) may find the initial costs prohibitive, posing a challenge to widespread adoption.

Implementing the necessary hardware, software, and connectivity infrastructure can incur substantial expenses. Return on investment (ROI) may take time to materialize, especially for smaller companies with limited financial resources.

Workforce Skill Gaps

The rapid pace of technological evolution can lead to skill gaps among existing employees. This is a significant challenge, particularly in industries where the workforce may have been accustomed to traditional manufacturing methods.

To address this, organizations need to invest in ongoing training and development programs. Upskilling the workforce ensures that employees can effectively operate and troubleshoot the new technologies integrated into the smart factory environment.

Moreover, the fear of job displacement due to automation and robotics can create resistance among workers. Clear communication and a strategic approach to workforce development are essential to overcome these challenges and foster a positive and collaborative transition.

Data Security Concerns

Smart factories heavily rely on interconnected systems and the continuous exchange of data. This increased connectivity exposes the manufacturing ecosystem to potential cybersecurity threats. Protecting sensitive data from unauthorized access and ensuring the integrity of the production process are critical concerns.

Cybersecurity threats can take various forms, including data breaches, ransomware attacks, or even sabotage of production processes. Manufacturers must implement robust cybersecurity measures, including encryption, access controls, and regular security audits to safeguard their digital infrastructure.

Standardization Challenges

Standardization is essential to ensure seamless communication and collaboration across the manufacturing ecosystem. Industry bodies and organizations are actively working to develop common standards that facilitate interoperability and the exchange of data between different components of smart factories.

The lack of standards can hinder scalability and limit the potential for collaborative initiatives across industries. Manufacturers, technology providers, and regulatory bodies must collaborate to establish and adhere to standardized protocols for smart manufacturing.

The Future of Smart Factories

Integration with Edge Computing

The future of smart factories involves greater integration with edge computing. This approach brings data processing closer to the source, reducing latency and enhancing the responsiveness of manufacturing systems. Edge computing is particularly crucial for applications that require real-time decision-making, such as robotics and quality control.

By processing data at the edge of the network, closer to the devices and sensors generating it, smart factories can reduce the reliance on centralized cloud computing.

Edge computing is beneficial in scenarios where immediate decisions are critical, such as autonomous vehicles navigating a factory floor or collaborative robot systems requiring real-time adjustments to their tasks

Sustainability and Environmental Impact

As sustainability becomes a top priority for industries smart factories are expected to incorporate eco-friendly practices. This includes optimizing energy usage, minimizing waste through predictive maintenance, and adopting green manufacturing processes to reduce the environmental footprint of production activities.

Smart factories can leverage data analytics and AI to monitor and optimize energy consumption across various manufacturing processes. By identifying energy-intensive operations and implementing energy-efficient technologies, manufacturers can contribute to both cost savings and environmental sustainability.

Continued Evolution of AI and Robotics

Artificial intelligence and robotics will continue to evolve, enabling smart factories to achieve higher levels of autonomy and efficiency. Advanced AI algorithms will enhance decision-making capabilities, enabling more complex tasks to be automated. Robotics will become even more integrated into daily manufacturing operations, performing tasks with increasing precision and adaptability.

Machine learning algorithms will continue to refine their predictive capabilities, allowing manufacturers to anticipate equipment failures and fluctuations in demand and supply chain disruptions. Enhanced predictive analytics will contribute to more agile and responsive production planning.

The integration of robotic process automation (RPA) into administrative tasks, such as order processing and inventory management, will further streamline business operations.