Converting small and medium scale enterprises, popularly known as SMEs, into Industry 4.0 is challenging. Such businesses include fewer than 250 people and thus face difficulties in proper financial resources, culture, R&D improvements, etc. Conducting a thorough survey of these companies is essential to know the level of development required for becoming a smart industry.

SMEs should witness this technological revolution to develop and maintain their market competitiveness. Any business model will benefit from Industry 4.0 by identifying, creating, and delivering value. Let’s see how to transform businesses to tackle this fourth industrial revolution.

Aspects to consider while converting businesses into Industry 4.0

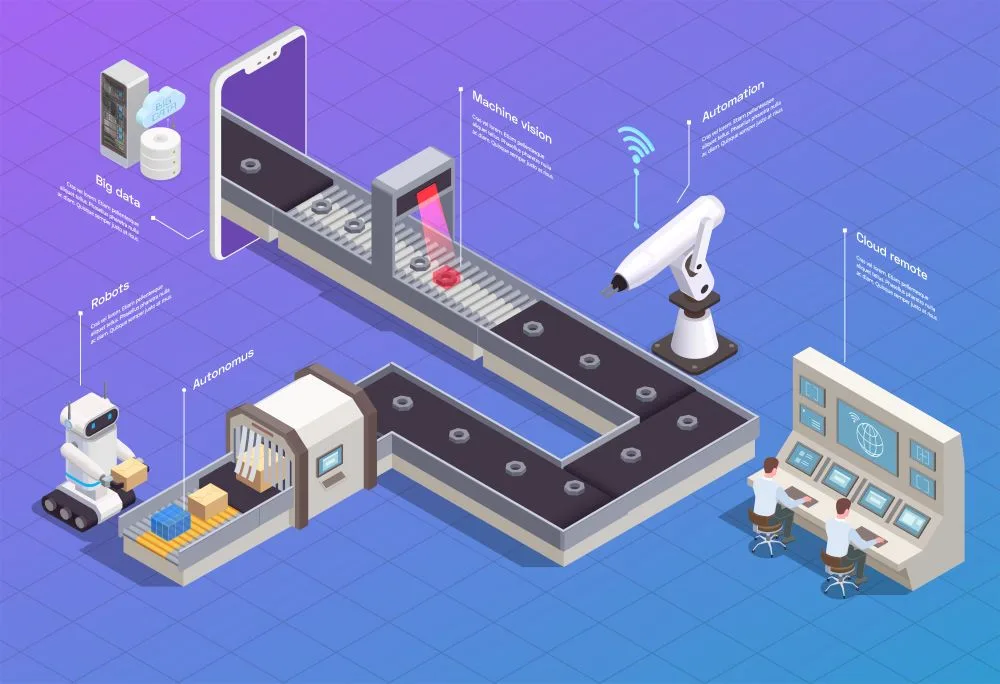

Automation

Currently, ever-expanding markets need flexible, adaptable, and agile processes. It can begin with the automation of production or smart factory implementation. It can provide the following advantages:

- Integration of physical and digital worlds

- Real-time data analysis with IoT

- Linking of people, systems, and machines in the single environment

- Advanced production planning, flexible manufacturing, and higher-quality products

Automation will bring positive changes in all the stages of businesses, such as marketing, logistics, production, shipping, SCM, etc.

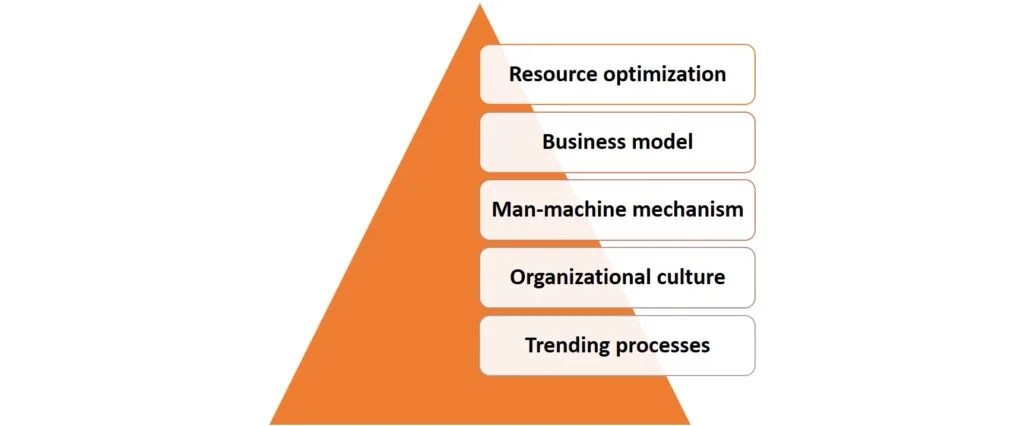

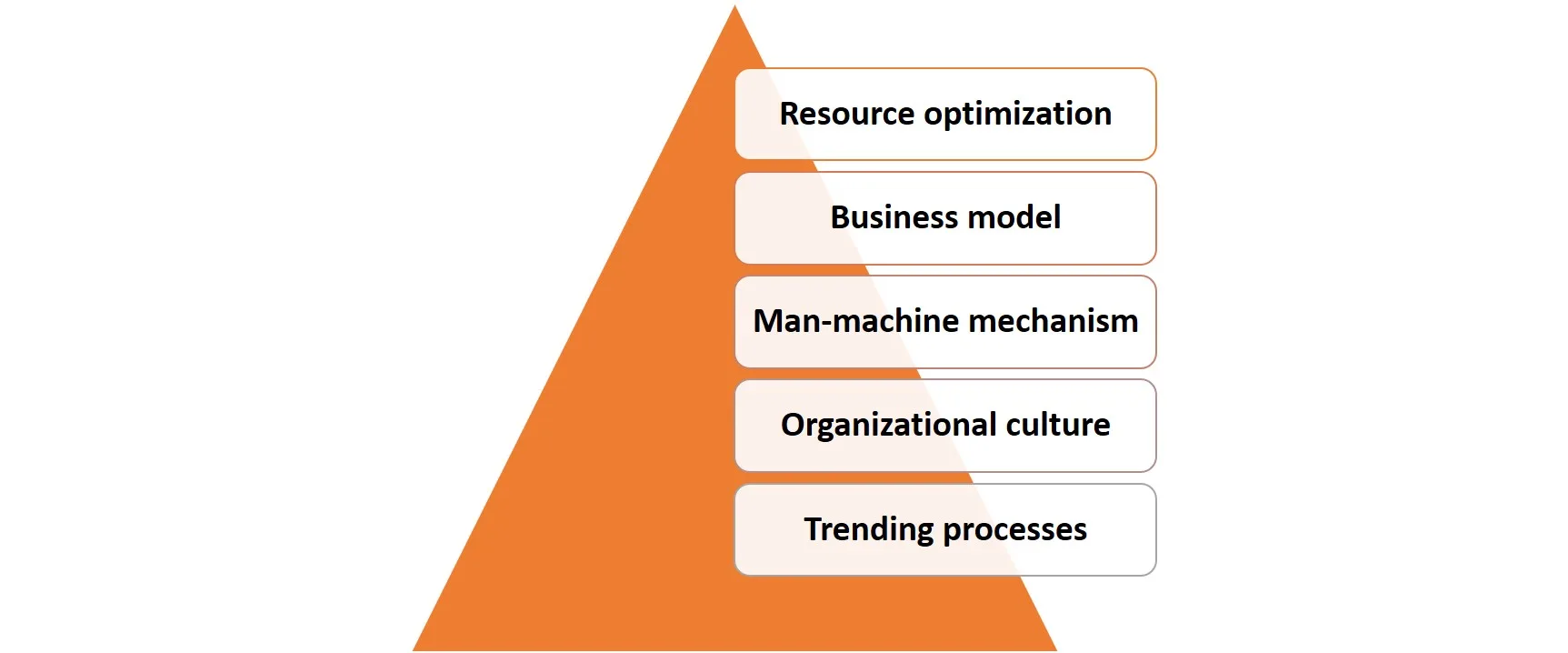

Migration tactics

A famous author named John Paul Kotter suggested an effective transitional plan to help the company move from its current production model to a more digitalized and intelligent one. There are several recommended strategies for migrating small and medium scale enterprises that can make the transition smoother. Forming a coalition, creating a vision with visual communication, and eliminating potential obstacles can help move the process forward. Integrate others by allowing them to contribute and generate short-term results to deepen changes and bring about institutional transformations.

Here are a few requirements:

- Resource optimization

- Interconnected business model

- Digitization of documents and all forms of communication

- Man-machine relationship mechanism

- Change in organizational culture

- Improved thinking approach toward end customer

- Revolutionary process implementation such as AI, Machine-learning, Augmented reality, Big data, etc.

The improved business model should cater to the value proposition, data management, creation of new standards, maximizing cyber security, and ensuring the business reputation.

Investment return

Achieving successful returns on investment is critical while running a business. As such, it’s crucial to take a personalized approach when migrating or digitizing any organization. Analyzing each element of the migration process and calculating expected returns for any investments made is vital to ensure success. It can range from technological investments to training management, process optimization, automation, etc.

Doing computations is necessary to determine the potential benefits of migration in each sector. With the help of such data, business leaders will have better options to decide on how to migrate into Industry 4.0 and optimize return on investment.

Here are some recommended things to know:

- Study of the present situation of the company

- Clear goal setting

- A detailed plan to accomplish the set plans

- Investment return calculation of each step

Taxes

Different government ministries, particularly those overseeing finance and economics are vigorously pushing for the digital transformation of corporations in various sectors. Several platforms have been developed to measure how each organization is advancing in its transition to Industry 4.0 and the hardships associated with this journey. An essential component of this fourth industrial revolution will be efficient resource utilization by government entities.

Each country has its own way of managing resources within its borders. It varies depending on cultural, social, and political factors and the control systems in place. This system relies heavily on taxpayer dollars, meaning the efficiency of this system is incredibly important. The finance ministries must upgrade their systems to become fully digitalized and employ new tools for resource & administration management. It is an essential step towards progress and modernization of the process.

The main focus is to streamline tax collection for maximum efficiency. Intelligent platforms and sophisticated management processes are necessary to ensure real-time & seamless information sharing across various industries during the production phase. The coordination of financial management between buyers and sellers can be facilitated by this system. Thus, all information is processed quickly and accurately. Having this in place helps to gain better insights into customer needs which adds to greater customer satisfaction.

Standardization

All small and medium scale businesses must work with a shared language for the successful standardization process. SMEs should thoroughly understand each element for properly managing their business models and attaining goals. To achieve an integrated system, we need to create a new culture of productivity. Existing standards such as ISO and IEC should transform and adapt to the changing smart environment.

To enable Industry 4.0, we must have the right technological enablers in place. It includes the essential pillars and other technologies such as 5G mobile communication and advanced management software systems like PLM, ERP, etc.

Economy

We are currently in the midst of a fourth industrial revolution, and its implications will touch every aspect of our lives. Of particular concern is the detrimental effect that traditional production models have on our environment, which can have severe repercussions for human life if unchecked. Industry 4.0 brings the possibility of revolutionizing and improving the conventional economic model – one which has been a major contributing factor to environmental pollution. We must be mindful that natural resources are finite and should stop overusing them or face dire consequences.

An expected outcome of Industry 4.0 is rising productivity which would lead to tremendous wealth. However, with this new prosperity must come an improved redistribution of resources through proper fiscal and tax control from government agencies. Small and medium scale enterprises must be wary of overproduction and exploiting natural resources as they can affect the environment.

Our current economic model focuses on three main goals: protecting our natural capital by efficiently utilizing renewable resources, maximizing the use of particular resources, and striving for an efficient system with a reduced environmental footprint. This system seeks to eliminate external and internal factors that could cause unnecessary harm to our environment.

Read more, about 6 types of leading green energy sources.

Legal Challenges in Industry 4.0

It’s widely known that scientific and technological advances are taking place more quickly than the legal environment or the countries’ constitutions. As a result, the legal framework should adapt and continue evolving alongside these changes. Nevertheless, digitalization presents customers with various new challenges. Small and medium scale enterprises must alter their methodology and the way they interact to adjust to these changes.

As technology advances, it is increasingly important to consider values and ethics. The fourth industrial revolution is largely focused on information management, regulation processes, and the adaptation of legal systems to the digital world – this will require a lot of work with respect to these topics.

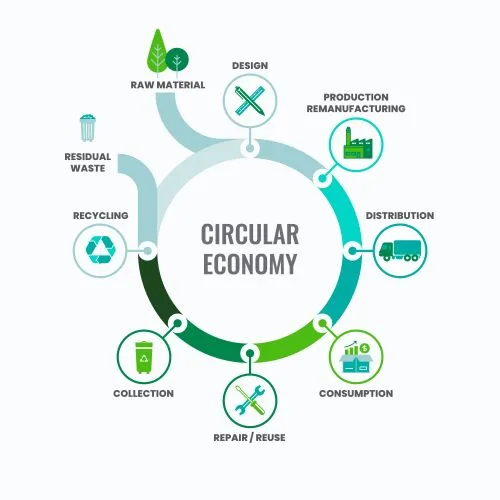

Circular economy

The circular economy is being embraced in Industry 4.0, marking a vast shift in the development of modern society. As part of this new approach, concepts such as waste and disposal have been re-evaluated – giving place to reuse and recycling.

Zero waste is a significant part of this society, where nothing goes to waste, and every item is viewed as a resource for the production process. It means maintenance, adaptation, and rejuvenation will be regular activities for everyone in this environment. In addition, innovating, reusing, and preserving will all become part of everyday life.

These are the primary aspects to look out for while transforming your small and medium scale enterprises.

If you are interested to know about any other aspect of small and medium scale enterprises, please write to us in the comment section.

[…] Read more about how to convert small and medium scale enterprises into industry 4.0. […]

[…] If you are interested in learning about converting businesses into Industry 4.0, read our article on how to convert small and medium scale enterprises into Industry 4.0. […]

[…] Read more about how to convert small and medium scale enterprises into Industry 4.0. […]