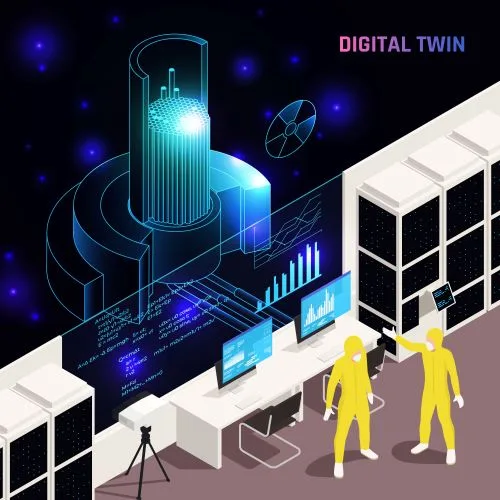

Digital twins (DTs) are a hot topic in the tech world that can revolutionize lifecycle management and predictive analysis across various industries and domains. With the power to provide exceptional insight into complex systems and their interactions, these virtual doppelgangers offer substantial benefits for users and stakeholders. DTs are everywhere, from smart cities and freight logistics to medicine, engineering, and automotive. In this article, we’ll delve into the deep end of the DT pool, exploring the integration and maturity levels across various domains. It will offer a view of this technology’s limitations, challenges, trends, and a domain-specific review of its applications.

This concept is leading the Industry 4.0 revolution, leveraging state-of-the-art data analytics and the seamless interconnectivity of the Internet of Things (IoT). It is transforming the manufacturing, healthcare, and smart city fields, paving the way for a data-driven future. The Digital Twin can bridge the gap between IoT and data analytics, thus creating a virtual twin connected to its physical counterpart. This way, it revolutionizes real-time decision-making and facilitates rapid analysis. The Digital Twin is the key to unlocking the full potential of IoT and navigating the era of the fourth industrial revolution with confidence.

Application of digital twins

Medical

The latest developments in digital twins technology are transforming healthcare like never before. IoT devices are now cost-effective and easier to use, resulting in skyrocketing connectivity. This connectivity is boosting the possibilities of utilizing Digital Twin in the medical field. One of its futuristic applications is creating a virtual replica of a human body that provides real-time analysis. Meanwhile, its current usage involves imitating the effects of particular drugs. Digital Twin is also being used to plan and execute surgical procedures. Additionally, healthcare professionals are studying it to conduct research, simulate various environments, and diagnose patients precisely.

Digital Twin technology can make intelligent predictions and decisions using AI (artificial intelligence) algorithms. Although many applications do not directly impact the patient, they have the potential to provide ongoing treatment and care. From bed management to large-scale ward and hospital management, Digital Twin for healthcare has limitless potential. Whether it’s predictive maintenance or repair of medical equipment, it can save lives by facilitating real-time and historical data-driven decision-making. Various crossovers and intended uses of this trend can verify its adaptability to different circumstances. The expansion of artificial intelligence, IoT, and Industry 4.0 has led to the growth of Digital Twin technology.

Read more, and know about these 11 IoT FAQs to be smarter.

Smart cities

The use of Digital Twins in smart cities is increasing rapidly due to advancements in IoT connectivity. Therefore, the potential of digital twins is also rising due to the development of smart cities. The data gathered from IoT sensors can enhance advanced AI algorithms and help with future-proofing. This data also provides insights into how utilities are distributed and used, helping with energy-saving efforts.

This technique can create a living testbed within a virtual twin, testing scenarios and allowing for learning from the surroundings by analyzing changes in the collected data. As smart city development continues to increase connectivity and the amount of usable data, the potential for Digital Twins becomes more viable.

Read machine learning approaches such as supervised, unsupervised, and reinforced in our article, a guide to machine learning fundamentals.

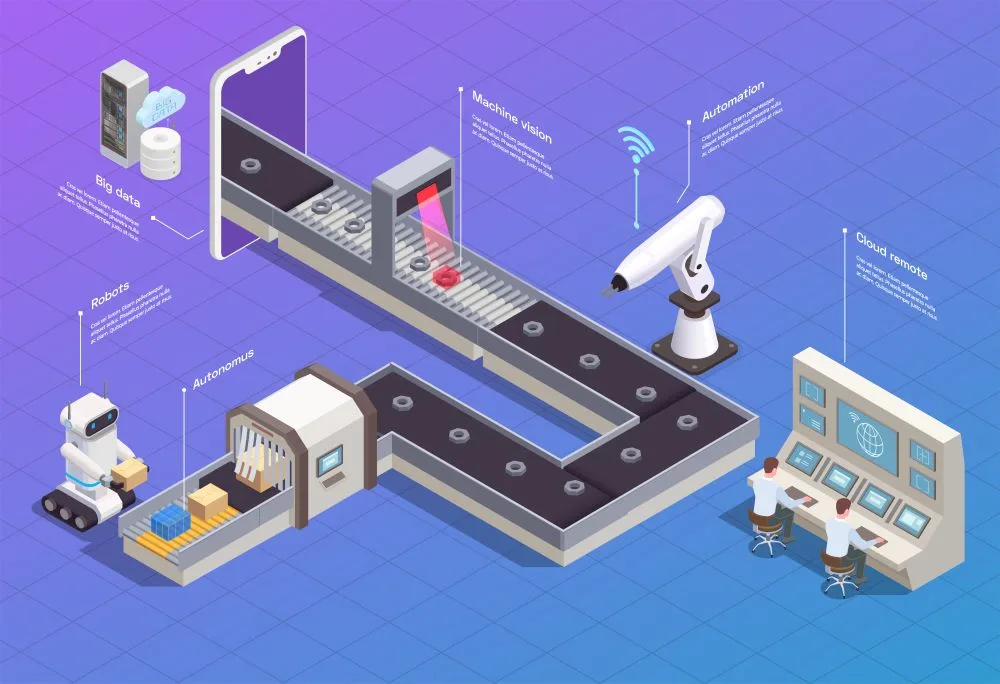

Manufacturing

Digital Twin technology is becoming vital within the manufacturing industry, as companies are searching for ways to improve productivity while reducing costs. With the advancements of Industry 4.0, the fourth industrial revolution, Digital Twins are designed for manufacturing operations. It allows manufacturers to observe machine and production line performance, anticipate issues earlier, and raise reliability and efficacy. When combined with AI algorithms, it can provide even greater accuracy in performance and prediction analysis, as machines can store large volumes of data.

Digital they are used to simulate and analyze the performance of engines and car parts. Similarly, the construction industry finds it helpful in creating smart city buildings and structures, as real-time simulations lead to greater precision in foreseeing and supporting facilities and structures. The overarching purpose of Digital Twins is to enable real-time simulation rather than relying on static blueprint models that lack real-time parameters, which limits their predictability and understandability. Similar to digital twins, there are other manufacturing trends, such as Industry 5.0, extended reality, cobots, etc., that are widely used in companies.

If you are interested to learn about the steps involved in transforming your businesses into Industry 4.0, read our article on how to convert Small and Medium scale Enterprises into Industry 4.0.

Challenges in digital twin

Several challenges are associated with this technology due to the heavy reliance on the following factors:

Useful Data

The hurdle in building a Digital Twin lies in acquiring quality data. The data must be reliable, free from errors, and must have a continuous flow without interruption. If the data is of subpar quality or inconsistent, the Digital Twin might not be able to perform optimally since it would be working with flawed and/or missing data. The quantity and standard of IoT signals are crucial in determining the adequacy of a Digital Twin’s data. Correct planning and analysis are necessary to confirm the relevant data to ensure the smooth operation of Digital Twin.

Every day approximately 2.5 quintillion bytes of data are created. Learn more about 4 critical applications of Big Data Analytics.

Trust

Trust is a crucial element that both organizations and users must nurture to fully embrace the Digital Twin concept. The key to overcoming trust-related issues is to educate people on its foundational aspects to make them appreciate the benefits of Digital Twins. Another critical step is to validate the model to ensure that it is operating optimally. Such steps will go a long way in boosting user confidence in the technology and improving trust levels. By embracing enabling technologies, we can guarantee that privacy and security practices are upheld throughout the development process. This restores the trust and confidence of users in Digital Twins.

IT Infrastructure

Just like the other cutting-edge technologies of analytics and IoT, the Digital Twin experiment also encounters a significant limitation- the current IT infrastructure. To run seamlessly, it needs a rock-solid infrastructure that enables IoT and data analytics to function efficiently. Without a well-designed, interconnected IT infrastructure, the Digital Twin becomes an exercise in futility as it would not achieve its set goals effectively.

For massive data storage and handling, businesses can use cloud-based services that access storage, computing power, and software without investing in physical hardware. Read more at 9 types of Cloud Computing Services to watch out for.

Privacy and Security

In the industrial domain, protecting privacy and security in the world of Digital Twins poses an important concern. This is because of the copious amounts of employed data and the inherent threat of sensitive system information. To conquer this, the dependent trends of Digital Twins- IoT and data analytics- must remain up-to-date with the latest security and privacy regulations. By accounting for the safety considerations involved with Digital Twins, we can take steps toward satisfying conviction.

If you want to avoid a greater risk of data breaches, theft, and fraud, cybersecurity is a viable option. It shields information, personal data, and everything available on the internet-connected system.

If you have any queries related to any aspect of the digital twin technology, please write to us in the comment section.

[…] big data. Another achievement is the Shanghai clone which has an area of 3750 sq.Kilometers. This digital twin is made with real-time data from sensors, drones, and satellites. It has the power to simulate […]

[…] like digital twins and augmented reality are likely to be responsible for such a massive […]

[…] IoT is integrated with data analytics, it forms digital twins. This can create a virtual replica of the human body that provides real-time analysis. Healthcare […]