Inventory is a term that indicates the number of objects kept in supply. This term is popular in several industries like manufacturing, retail, e-commerce, etc. In ancient times, vendors and dealers used to maintain handwritten notes for keeping the track of goods. Then slowly, after the second industrial revolution, the need for inventory management began to take shape. The first punch card was created by Herman Hollerith in 1889. It was helpful to track the variety of information. This tactic inspired the students from Harvard University, and they developed a check-out system using a punch card. It was the first-of-its-kind inventory management tool.

This article will tell you everything about inventory, its purpose, its types, and the reasons for holding stocks.

What are inventories and stocks?

Stocks are simply the storage of materials. Consider, for instance, a vendor purchases goods or objects from a dealer and stocks them until selling to the customers. Every organization holds stock to carry out their businesses. It can be any shop, industry, showroom, or any other company. Stock is something that is not used or sold immediately. It is stored for future usage.

Inventory consists of all the items listed as stocks. These two terms might be confusing. It has become increasingly common to use this term both for the stock itself and the list of items. Some industries have adopted different nomenclature for stocks as provisions, backups, reserves, stores, etc. It comprises different items retained in stock. A TV showroom, for example, may have a 32 inches TV as a separate item in inventory. It can also have 40 inches and 42 inches TVs as distinct entities. Again, this may differ with the unit of products.

- Items are specific products that are kept in stock

- A unit is a measure of the quantity or size of an item.

All kinds of stock need some sort of control. Various companies can have finished products, raw materials, WIP items, data, employees, documents, and all other essential stuff. Let’s refer to all such items as materials regardless of the type of company.

Why do people hold stock?

It is due to a number of reasons specified below:

- Delivering products on time to customers

- Compensating for unexpected demands

- Buying items that are on their way out of production or are hard to come by

- Reducing transportation expenses and making full loads for supply

- Allowing variations between the actual demand rates and best supply rates

- Purchasing materials at a low cost to sell them at a higher price in future

Matching supply with demand is one of the important traits of Lean manufacturing.

Types of stocks

Types of stocks can vary from company to company. The most typical classification is as follows:

- Raw material: These materials arrive from suppliers and are stored until required for manufacturing.

- WIP: Work in progress means the materials that are presently being utilized.

- Finished goods: These are the manufactured products that are awaiting shipment.

Note that all these classes are not present in all industries. Some supporting materials can also be categorized as:

- Consumables: Things that support the ongoing operation.

- Spare parts: Entities that repair or refurbish the damaged part.

Consider manufacturing a car.

- Raw materials: Aluminum, magnesium, copper, plastics, composites, etc.

- Spare parts: Wiring harnesses, Window Regulators, AC Hoses, fuse boxes, etc.

- Consumables: Oil filters, Transmission fluid, Power steering fluid, etc.

Significant points about stock

The scope of the usage, quality, and conditions of stocks differ according to the industries.

- Rocks and sands need larger storage space but no attention

- Frozen foods require a specialized type of storage

- Pricey items like gold and diamond require a little space but a tight security

Regardless of these things, the stock is a vital component of every operation. It streamlines the process making it more efficient.

- They drive profits, return on investments (ROI), and every financial aspect by impacting operational costs.

- Stocks improve customer satisfaction, quality of products, and market presence by ensuring adequate lead time and material availability.

- They can provide specialized services to suppliers, third-party organizations, and other intermediaries to facilitate their business expansion.

- Companies cannot function without stocks. As a result, the scope of inventory management has widened.

If you want to learn more about the quality of products, refer to the 15 most valuable terms to understand ISO 9001:2015.

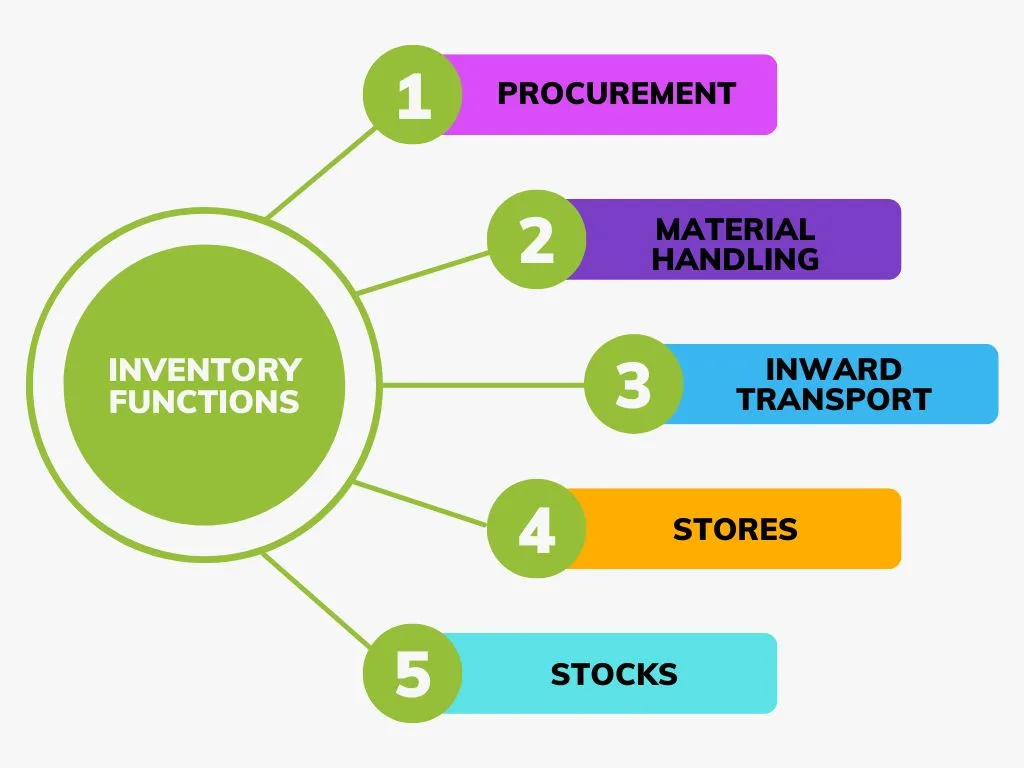

Common function of inventory management

Inward transport

Materials are transported from suppliers to receiving areas in the organization. There are several crucial decisions to make, such as the mode of transport (road, rail, air, etc.), outsourcing policies, choice of the transport operator, route, safety, and legal requirements, timing, and cost.

Material Handling

In this phase, received materials are sent to stores. It also focuses on the material movement from stores to the required operational area. It comes with efficient packaging and handling skills that ensure smooth material movement using proper tools.

Procurement

In most cases, it starts the flow of materials through an organization by sending a purchase order to a vendor. The procurement department is responsible for finding suitable suppliers, negotiating terms, setting conditions, organizing delivery, arranging insurance, authorizing payment, and doing everything else necessary. The job previously involved clerical work and order processing. But now, it is regarded as a significant link between suppliers and major expenses.

Receiving

It ensures checking the material as per the order, accepting receipts, unloading shipments, inspecting quality, and sorting them.

Stocks

It establishes the stock policies, including the types of material to store, assets, customer service, stock levels, order sizes, and order timing.

Stores

Warehouses or stores are responsible for keeping materials in stock until they are required. It ensures that materials are protected from adverse conditions, packaged properly, and easily accessible.

These functions are applicable to work in progress. Once the finished goods are ready to be shipped, other functions like communication, outward, physical distribution, packaging, etc., come into the picture.

Often, these activities overlap and are closely related. It makes no sense to divide them artificially but to see them as different aspects of a single logistics function. There is a direct impact on stocks from all logistics activities.

[…] Excess stock of raw materials, work-in-progress inventory, and finished products. This leads to huge expenses, numerous defects, and surplus storage […]

[…] in the Toyota production system. The intent of kanban cards was to limit the work-in-progress (WIP) inventory. Since then, it has become a core of every manufacturing system. Kanban can appear in two […]

[…] Inventory management […]

[…] FMEA. It has wide scope considering many processes like operations, transportation, SCM, quality, stocks, repair, maintenance, […]